By: Don Garno, Custom-Fabrication Product Manager

Over the past 6 months, I have spent a lot of time discussing the advantages of the custom-fabricated Duro-Last® in comparison to traditional roll good materials with contractors in the field, sales representatives and even fellow employees. The main theme that I have taken away from each of these discussions has been centered on up-front cost. While everyone that I’ve talked to loves the advantages that our custom-fabricated accessories and membrane provide, the cost of these items can pose a challenge for budget-conscious projects. Let’s explore the key attributes of Duro-Last’s custom-fabricated products and how they address these cost challenges:

- Less Waste –With custom-fabricated deck sheets and parapets, the attachment tabs are included in the square-foot price. In comparison, roll good membranes do not have this cost built in, meaning that every seam overlap costs an additional 6” of material that must be added to the total cost per square-foot. This is typically an additional 6% to 11% increase in material needs over custom-fabricated deck sheets for the same surface area.

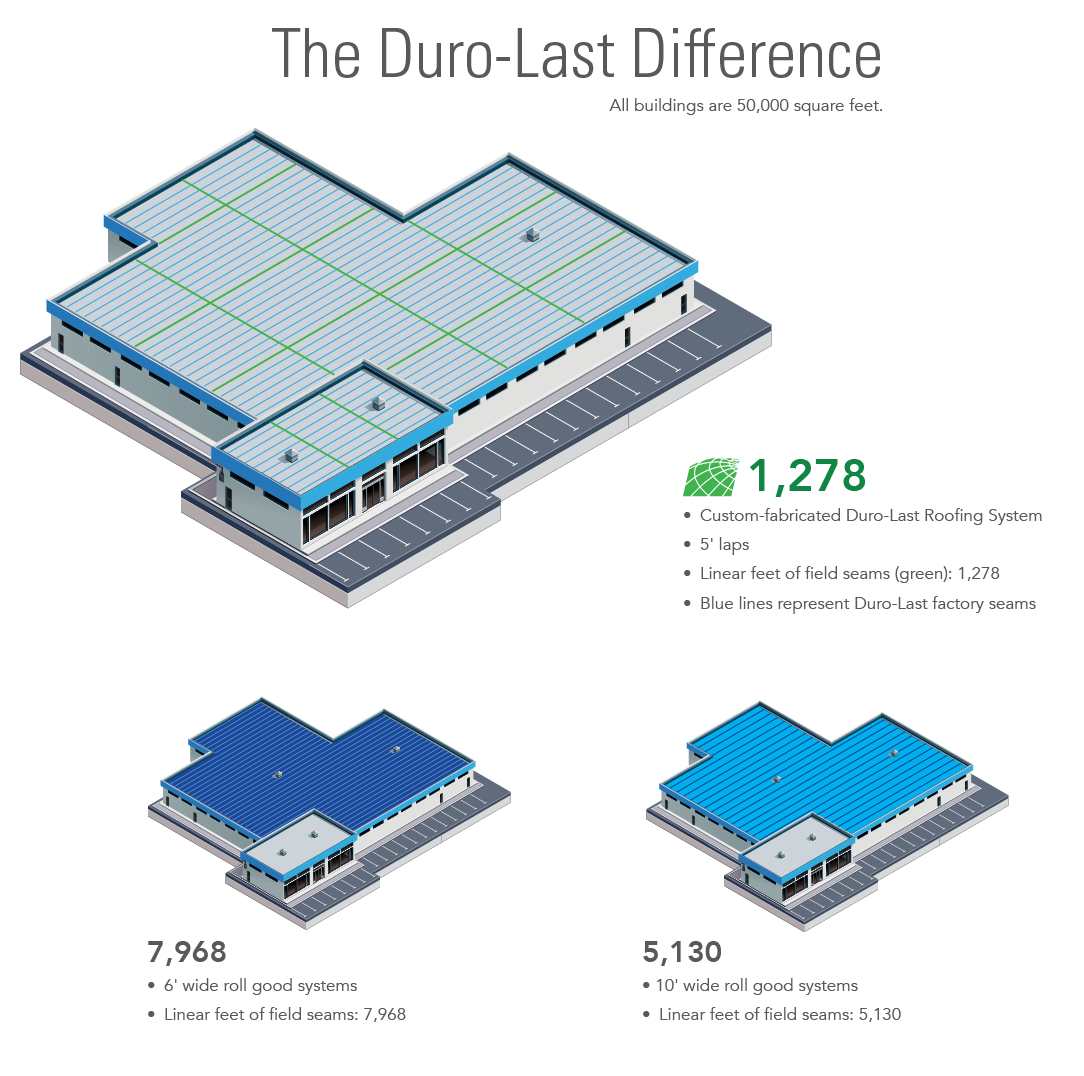

- Less Seams–With Duro-Last’s custom-fabricated deck sheets, up to 85% of the seams can be completed in our factory controlled environment. This eliminates a majority of the rooftop seaming needed when using traditional roll goods, saving significant labor costs and reducing the likelihood of costly callbacks. While many contend that today’s rooftop equipment is far superior than it was in the past, variable field conditions and efficiencies will never be able to match the ideal conditions of a factory-welded seam. Put simply, the labor savings of custom-fabricated deck sheets are greater than even the most efficient rooftop equipment.

- Recyclability– Mechanically-attached Duro-Last membranes are recyclable through our Roof Take Back Program, meaning disposal costs are all but eliminated and the environmental impact is significantly reduced.

- Energy Efficiency–It’s important for building owners to understand the full cost of their roofing investment, even after the installation is complete. Duro-Last’s white membrane roofs are highly reflective, which can greatly reduce energy consumption and electricity bills. Coupled with the labor savings and long-term performance offered by Duro-Last membranes, these cost savings can significantly offset the up-front investment of a custom-fabricated Duro-Last Roofing System.

- Added Value–Duro-Last’s unique products and proven history add value to the cost of a new roofing system that can’t be overlooked. The custom-fabricated Duro-Last Roofing System has long-lasting durability and serviceability, proven over our strong 40 yearhistory. And our custom-capabilities mean that we can provide solutions for even the most unique applications; saving time and labor for rooftop crews that would have to field-fabricate these custom solutions otherwise.

- Consequential Damages–By selecting the custom-fabricated Duro-Last Roofing System, building owners secure our Supreme Warranties, which include coverage for consequential damages. Building owners can rest assured that their custom-fabricated Duro-Last Roofing System will keep them covered for years to come, and that security is worth every penny of the investment.

While the debate between custom-fabricated materials and roll goods is far from over, the advantages of a custom-fabricated Duro-Last Roofing System can’t be denied. When meeting with building owners to discuss these advantages, take the time to walk them through the entire lifecycle cost of their investment, not just the up-front cost. Utilize the materials available on the Duro-Last Storefront to demonstrate the custom-fabrication advantage from the rooftop to their bottom-line. Highlight the hidden cost savings that can make a big impact. And as always, contact me for support whenever it’s needed.